If your Whirlpool washer is malfunctioning, the issue may lie with the control board. Understanding the signs and taking the right steps can help you tackle the problem effectively and potentially save on repair costs.

Understanding the Control Board

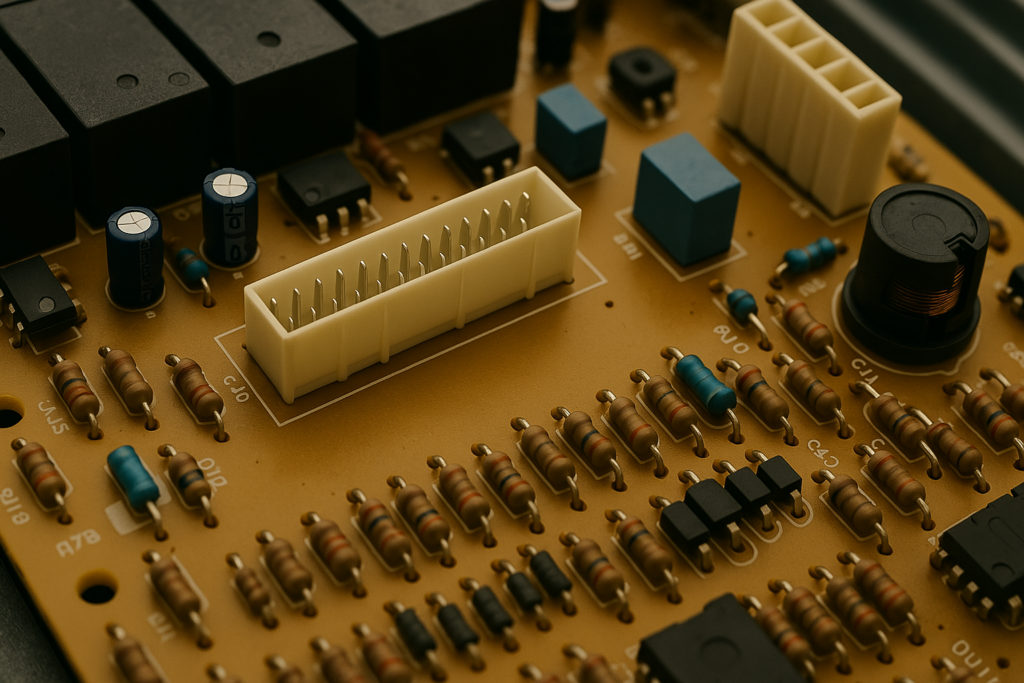

The control board serves as the command center for your Whirlpool washer. It coordinates the washer’s functions by sending signals to the motor, water pump, and sensors. From starting a cycle to completing the final spin, the control board keeps each step in sequence.

Over time, wear and tear, power surges, or water exposure can compromise its performance, leading to various issues that affect the washer’s operation.

Common Signs of a Faulty Control Board

A malfunctioning control board may present several symptoms, ranging from minor inconveniences to significant disruptions:

- The washer won’t turn on: If your machine shows no signs of life, the control board might be the issue.

- Unresponsive buttons or controls: When the buttons fail to work or respond inconsistently, the board may be struggling to communicate with the system.

- Error codes that persist: Recurring or unresolvable error codes can indicate a faulty board.

- Cycle interruptions: The washer stopping mid-cycle or behaving unpredictably can point to control board issues.

- Burning smell or visible damage: A burnt odor or noticeable damage on the board is a clear sign of failure.

Potential Causes of Control Board Malfunction

Understanding what might have led to the issue can help you prevent future problems. Some common causes include:

- Power surges or voltage fluctuations: These can overload and damage the sensitive components of the board.

- Water exposure: Moisture from leaks or humidity can short-circuit the board.

- Age and wear: Over time, the components may degrade and stop functioning properly.

- Physical damage: Accidental impacts or mishandling during maintenance can harm the board.

- Faulty wiring connections: Loose or frayed wires can disrupt the flow of signals.

Safety Precautions

Working on your washer requires careful attention to safety. Keep these guidelines in mind to prevent accidents or further damage:

- Power off the appliance: Unplug the washer or switch off the circuit breaker before starting any repairs.

- Use insulated gloves: These can protect your hands from sharp edges and electrical hazards.

- Keep the workspace dry: Never handle internal components with wet hands or in a damp area.

- Maintain organization: Keep your tools and workspace tidy, and keep pets and children out of the area.

- Consult the manual: Refer to the user guide for specific instructions related to your model.

- Take photos or notes: Document the wiring connections before disconnecting anything to simplify reassembly.

- Wear safety glasses: If handling debris or chemicals, protect your eyes from potential harm.

- Let the machine cool: If recently used, allow any heated parts to cool down to avoid burns.

- Handle with care: Avoid using excessive force when working with delicate components.

- Use proper tools: Rely on non-conductive tools when working near exposed wires or terminals.

Read more: Troubleshooting the Door Lock F22 Error on Your Whirlpool Duet Washer

How to Test and Replace a Whirlpool Washer Control Board

Here are the steps to test the control board for faults and replace it if necessary:

Test the Control Board

- Check the Power Supply

- Verify the washer is plugged into a working outlet.

- Test the outlet by plugging in another appliance to confirm it is supplying power.

- Inspect the washer’s power cord for damage, such as frayed wires or loose connections.

- Replace the power cord if it shows signs of damage.

- Inspect the Control Board Visually

- Unplug the washer from the power source.

- Remove the back or top panel of the washer (refer to the user manual for your model).

- Locate the control board, usually housed in a plastic casing.

- Look for scorch marks, burnt components, or other physical damage on the board.

- Test the Control Board with a Multimeter

- Refer to the wiring diagram in the washer’s manual to identify the pins corresponding to key circuits.

- Set the multimeter to continuity or resistance mode.

- Place the probes on the specified pins and check the readings.

- Compare the readings with the specifications in the manual. If they do not match, the control board may be faulty.

- Rule Out Other Causes

- Test the lid switch to check if the lid lock mechanism is functioning properly.

- Verify the water level sensor is sending accurate signals to the control board.

- Inspect the motor or pump for damage or wear that might cause similar issues.

- If these components are operational, the control board is likely the issue.

Replace the Control Board

- Disconnect the Old Control Board

- Take a picture or make notes of the wire connections to the control board for accurate reassembly.

- Carefully unplug the wire harnesses, using needle-nose pliers if needed to avoid damage.

- Remove screws or clips securing the control board.

- Take out the old control board.

- Install the New Control Board

- Align the new control board with the mounting holes.

- Secure it using the screws or clips from the old board.

- Reconnect the wire harnesses to their corresponding ports and confirm they are properly connected.

- Refer to the pictures or notes to double-check the connections.

- Reassemble the Washer

- Reattach the panel removed earlier and secure it with screws.

- Move the washer back into position.

- Reconnect the water supply lines.

- Test the Washer

- Plug the washer back into the power outlet.

- Run a test cycle to verify the new control board is functioning correctly.

- Confirm the washer powers on, responds to controls, and completes a full cycle without issues.

Benefits of Addressing the Issue Promptly

Delaying the repair of a faulty control board can lead to more significant problems and higher costs. Taking timely action offers several benefits:

- Extends the lifespan of the washer: Prevents further strain on other components.

- Improves performance: Restores the washer’s ability to complete cycles without interruptions.

- Reduces energy consumption: A well-functioning washer uses energy efficiently.

- Prevents costly replacements: Fixing the board early can avoid the need to replace the entire appliance.

- Minimizes inconvenience: Quick repairs reduce downtime and keep your laundry routine on track.

Read more: How to replace common Whirlpool washer parts

What’s Next?

When your Whirlpool washer starts acting up, it can feel frustrating to deal with the issue. The problem might actually be with the control board, and fixing it could be simpler and less expensive than you think. Spotting signs like error codes, unresponsive buttons, or odd smells early can save you a lot of trouble and expense.

Handling the repair sooner rather than later keeps your washer working properly and prevents bigger problems. With some patience and basic tools, you might be able to fix it yourself and avoid replacing the entire appliance. Instead of giving up on your washer, consider taking the steps to repair it and get it back to running smoothly.